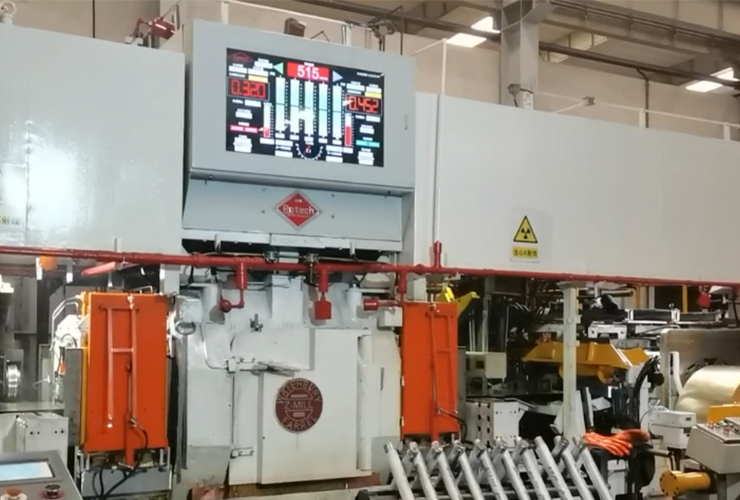

At present, the upgrade and renovation project of the WF 20 roll and four roll precision rolling mills undertaken by our company for Jinwei Copper Industry of Tongling Nonferrous Group has successfully passed the acceptance of the owner.

The upgrade and renovation of the two imported rolling mills involved a wide range of aspects. Shanghai Luoling and the owner's team worked together to overcome difficulties such as time constraints, heavy tasks, and equipment aging caused by thorough confirmation and careful design in the early stage. Within the expected time, they successfully completed the owner's commission and achieved the restoration of uncoiling function, low tension rolling, maximum speed rolling, automatic input of plate shape, residual oil rate, and improvement of product quality of various materials. They also achieved the goals of improving quality and efficiency, improving quality, and ensuring stable and high production as planned for the upgrade and renovation of the two rolling mills.

After nearly four months of shutdown renovation and trial production debugging, the acceptance testing work has been successfully carried out, and all indicators meet the contract requirements. This marks the complete success of the upgrade and renovation work of the 20 roll and four roll rolling mills, providing strong support for Jinwei Copper Industry to further improve its precision processing capacity. During the renovation period, the solid work style and good team spirit of the Shanghai Luoling team received unanimous praise from customers, and also verified the technical strength of the Shanghai Luoling team for complex renovation projects such as imported rolling mills.